Single PC Weight Starts From few Grams to 3000 KGS

Process

The essence of planning, procurement and production as per time schedules are inculated and therefore it brings about a perfect co-ordination among the various departments of the company to achieve well defined targets in an exemplary manner and to provide utmost product satisfaction.

Pattern Making

We are using teakwood,Alumimium for pattern making. The patterns are made as per customer drawing. The split line and contraction allowance are decided by SAGPL, Patterns are manufactured with our approved subcontracted Service. We have our own pattern shop to provide method for new development and to made ready to issue pattern to production.

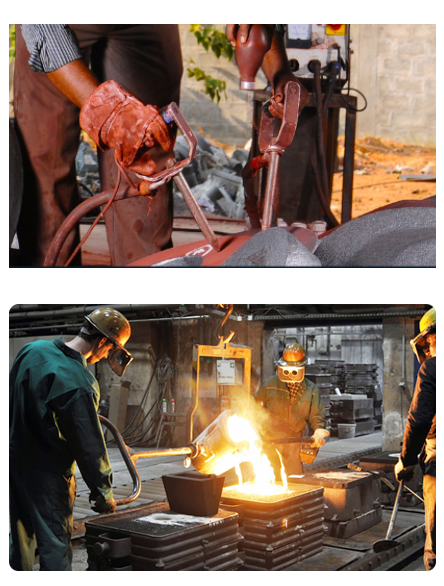

Mould & Core Making

Mould & core making process to chemical bonded sand system with continuous mixer is from IMF make and its capacity to deliver 30 Ton mixed sand per hour and sand recycling Process control activites are performed are in place to ensure the right quality of product at the right time.

- Carbon dioxide Silicate Process

- Chemical bonded Sand Process

Steel Casting

Our approved Steel Casting foundries have maintained a state-of-the-art Foundry including

- In-house pattern shop

- Modern machine shop and Testing

- In-house facility backed by Generator

- Wind Power for non stop production.

Capacity

- Steel Casting - 400 Tons /Month

- Single PC Weight Starts From few Grams to 3000 KGS

Pattern Shop

- Patternshop features highly trained pattern makers from the simple to the extremely complex casting design.

- Our patterns ensure accurate casting that meets Customer specifications.

- CNC machined patterns provide close & consistent casting tolerances.

- The Patternshop is strengthened with dedicated CNC machine for full time pattern making from solid models and Simulation software SOFT CAST 3.5 for methoding.

- We SAGPL handle 6,500 active patterns.

Moulding Process

- Sodium Silicate / CO2 & Resin bonded (No Bake)

- Shell Process

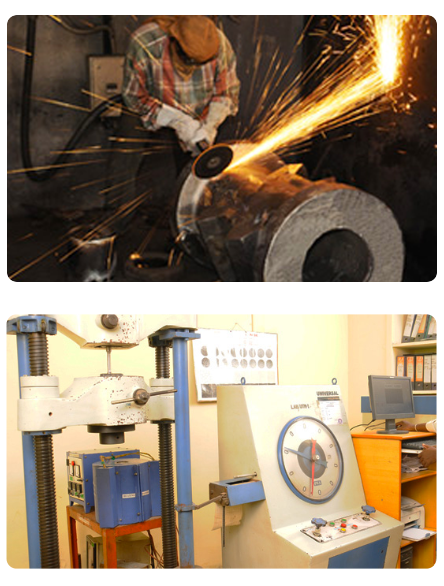

Fettling

- Full Fledged In-house Fettling

- Arc Cutting

- Gas Cutting

- Grinding

- Dressing Facility -Steel Shot Blaster

- Qualified and Approved sub-Contractors

Core Practice

- Sodium Silicate / CO2

- Shell Process

- No-Bake

Heat Treatment

- Oil Fired

- Electrical & Muffle Electrical Furnaces

- Water quenching tanks

PLANNING, PROCUREMENT AND PRODUCTION

Melting Unit

Equipped with 150 Kgs, 500 Kgs, 1500 Kgs, 3000 Kgs & 5000 Kgs Induction Furnace Immersion Type Prometer is used to maintain the temperature control.

Heat Treatment

We have five various capacities ranging from 3 to 5MT Electrical operated Heat treatment furnace with Water & Air Quenching facility with time temperature recorder to control the process and the same are calibrated as per API 6 A & ASTM A991.

Shot Blasting

Hanger type shot blasting machines 4Nos are in use for blasting and cleaning the castings.

Fettling

Fettling shops is equipped with all essential finishing equipments of Swing frame Grinders,Hand Grinders,Chippers and welding rectifier.

For Material handling over haed cranes and mobile cranes are equipped in fettling shop.

.jpg)